In Hampton Roads, Virginia—a place best known for its shipyards, Navy roots, and hard-earned trades—a new kind of industry is quietly taking shape. It’s not another port or factory. It’s a space mining company. And its founder, Jason Hardee, isn’t your typical aerospace executive.

He’s a former trucker, construction equipment operator, self-taught engineer, and lifelong builder who’s spent years turning backyard ideas into practical systems. Now, with ExpoSol Corp., he’s turning his attention skyward—to the vast resources drifting through our solar system in the form of asteroids.

“We’ve mined this planet enough,” Hardee told me during our interview. “If we want to keep building without destroying everything that’s left, we need to look up.”

From Earthmover to Orbit Builder

Hardee’s background reads like the working-class backbone of America: mechanic, long-haul driver, tow operator, construction hand, and equipment handler. But make no mistake—he’s also deeply analytical and inventive. At one point, he was pursuing a degree in electrical engineering—he nearly finished, but life pulled him in another direction. That didn’t stop him from learning or innovating. Over the years, he tinkered constantly, building everything from experimental propulsion systems to materials processing rigs.

“I’ve always liked building things,” he said. “Not on paper—actual things that work. You run into problems, you solve them. That’s what industry is.”

ExpoSol is his most ambitious build yet. Based out of Hampton Roads—and working with the City and the Hampton Roads Small Business Development Center—ExpoSol is setting out to mine asteroids for high-value metals and shift the burden of resource extraction off Earth’s ecosystems. It’s a vision shaped not by science fiction, but by years of experience in the real world.

Why Asteroids?

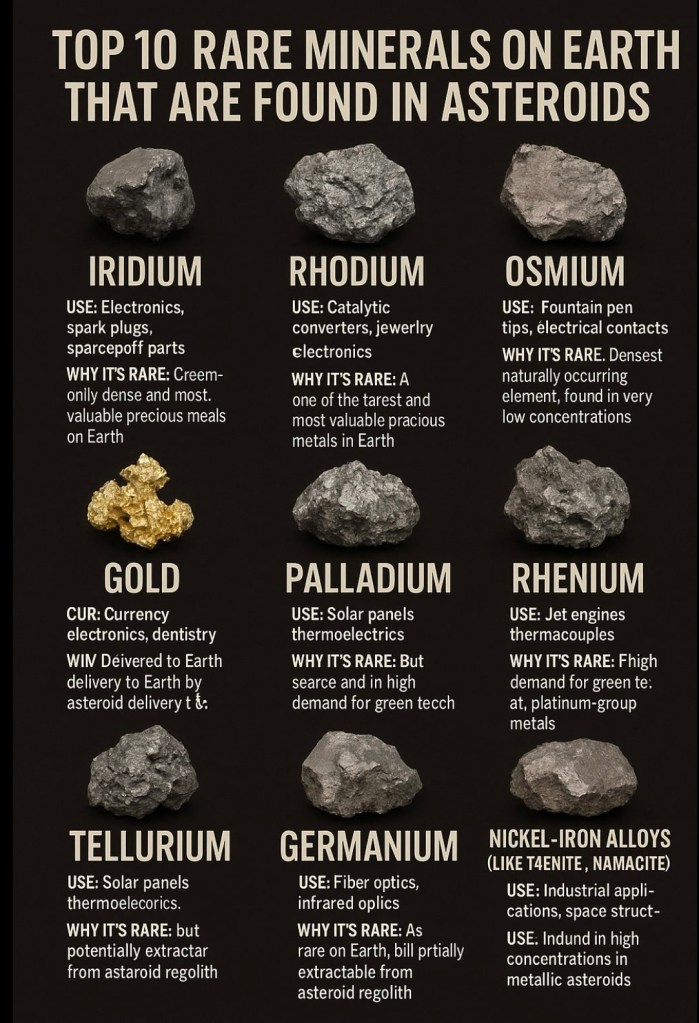

Asteroids contain platinum, iridium, gold, cobalt, and rare earth elements—resources that are becoming harder and more environmentally destructive to mine here on Earth. Instead of open-pit mines, toxic runoff, or deep-sea dredging, ExpoSol wants to extract these materials in space—where there are no habitats to destroy and no water tables to poison.

“Some mining will always need to happen on Earth,” Hardee said. “But we don’t need to be tearing up the ocean floor or cutting into rainforests for rare metals. We’ve got entire rocks in space made of the stuff.”

It’s more than an environmental argument—it’s a systems shift. Near-Earth asteroids are accessible with current propulsion. Once mining begins, the industry could support orbital refineries, shipyards, and even off-world habitats.

And that’s where ExpoSol sees itself: not just as a mining company, but as a critical piece of the infrastructure that will allow space industry to grow—ethically, sustainably, and profitably.

Built in Virginia, Designed for a National Mission

Virginia might not be the first place people associate with space tech, but Hardee sees it differently. Hampton Roads, he says, has the exact skill base asteroid mining will require: welders, mechanics, engineers, former Navy personnel—all trained to solve problems in extreme environments.

“We’re going to need people who know how to build, troubleshoot, adapt. Mechanics, operators, techs. People like me. People here.”

Why Virginia Makes Sense

Virginia offers a unique mix of assets that position it well for space industry growth: proximity to NASA Langley and Wallops Flight Facility, a deep-rooted military and naval workforce skilled in mechanical, electrical, and systems engineering, and a growing aerospace corridor supported by state and local economic development programs. For ExpoSol, this means access to talent, test infrastructure, and logistical support—all without leaving the East Coast.

While headquartered in Virginia, ExpoSol aims to be a national company—drawing on talent, industry partnerships, and supply chains from across the United States. The goal is to build a foundational sector of the American space economy, one that provides lasting jobs and leads in innovation on a global stage.

ExpoSol’s systems reflect that grounded mindset. Rather than chase unproven high-concept ideas, the company is adapting rugged, existing mining technologies for space conditions. Their standout innovation? A robust conveyor system that moves material efficiently from the cutting head into the ship—designed to handle floating debris, zero gravity, and no margin for error.

“Space is messy. If it can jam, it will jam. So we’re designing things to keep running anyway.”

The company plans to power its systems with RTGs—radioisotope thermoelectric generators. These compact nuclear batteries have powered spacecraft since the 1960s, and their reliability makes them ideal for operations far from the Sun and covered in asteroid dust.

“Solar power doesn’t cut it in those conditions,” Hardee explained. “RTGs charge our battery banks, and we work in cycles: charge, mine, process, repeat.”

Starship, Shipping, and the Path Ahead

Rather than build its own rockets, ExpoSol is aligning with SpaceX’s Starship program. These reusable launch vehicles—designed to send cargo to Mars—are being reimagined by Hardee’s team as asteroid mining freighters.

“Our plan isn’t to colonize Mars. We want to bring material from space back to Earth—and Starship gives us that ability at a fraction of the cost.”

With the right conditions and continued Starship development, ExpoSol estimates it could reach operational capability within two years. Near-Earth asteroids may require only four to six months for a round trip.

Before then, ExpoSol is focused on building and testing its hardware—and engaging the right partners and investors to move forward.

A Message to Investors: Tangible Tech, Real Markets

While the promise of asteroid mining is massive—billions in accessible materials—ExpoSol isn’t leading with hype. Instead, it’s offering something investors increasingly look for: clear engineering, real-world testing, and infrastructure that can scale.

“We’re not trying to sell a fantasy,” Hardee said. “We’re building systems that already work on Earth and adapting them for space. Durable, repeatable, repairable. This is supply chain work—just in orbit.”

It’s not only the materials that hold value. Whoever builds the first working systems for off-world mining, processing, and logistics will have the foundation to support dozens of future space industries: manufacturing, transport, energy, and agriculture.

Investors don’t just get a stake in metal. They get a stake in the scaffolding for humanity’s next economy.

Industry, Without the Footprint

ExpoSol’s mission is rooted in a simple idea: industry shouldn’t mean destruction.

Mining doesn’t have to come at the cost of clean water, stable forests, or functioning ecosystems. By shifting high-impact extraction off Earth, Hardee believes we can decouple growth from harm—and leave space to do what it’s always done best: carry the load.

“This isn’t about escaping Earth,” he told me. “It’s about protecting it.”

The Bigger Vision

In the long term, ExpoSol envisions a network of orbital facilities: prefabricated structures assembled in space, mining ships that return autonomously, and eventually, crewed stations where real people live and work. It’s a vision that includes shipyards, space-based agriculture, and deeper exploration beyond the asteroid belt.

But none of it happens without building the basics first: conveyor systems, energy storage, durable hardware that runs no matter what.

“People don’t realize how close this is,” Hardee said. “NASA and Japan have already returned asteroid samples. Now it’s about scale. Application. Consistency.”

The next step? A working prototype—built locally, tested rigorously, and designed to prove what’s possible. After that, a mission order. Then: space.

Final Thoughts

ExpoSol’s guiding principle is summed up in its simple but powerful slogan: “Leave no trace, mine in space.”

To learn more or follow their progress, visit www.exposolcorp.com or follow them on X at @EXPOSOLcorp.

In a world where tech headlines often oversell and underdeliver, ExpoSol is doing something rare.—building a serious, quietly ambitious project that begins not in a launch bay, but in a garage. It’s led by someone who’s welded the beams, run the cables, and driven the trucks—and who now wants to take that same muscle and precision to orbit.

“This is the beginning of a brand-new industry,” Hardee said. “Most people haven’t seen it yet. But they will.”

From the yards of Virginia to the silence of space, ExpoSol is working to make sure the next generation of industry doesn’t have to cost the Earth.

Thank you for taking the time to share your thoughts. Your voice is important to us, and we truly value your input. Whether you have a question, a suggestion, or simply want to share your perspective, we’re excited to hear from you. Let’s keep the conversation going and work together to make a positive impact on our community. Looking forward to your comments!